General

Short Description

Mobil Wood is a carpenter’s factory with 70 employees, specialized in the ecological fitting out of shops and solutions to develop bulk food. The building programme includes a factory and offices. The factory part covers more than 3500sqm and includes a wood workshop and a finishing workshop, a covered courtyard, and storage and shipping sheds. The offices cover approximately 300 sqm. A common space of 150sqm, at the interface between the factory and the offices, gives all users of the building the opportunity to meet.

Intentions

Enhance well-being and productivity:

For Mobil Wood, the economic value created by the factory’s production is inseparable from the human value of the company. Indeed, it is a question of combining efficiency and production functionality with the well-being and quality of life at work.

All comfort parameters were considered to ensure that the workspaces are both pleasant and ergonomic

Building designed as a material bank:

The building is design as a material bank, that means:

- products and materials are selected for their renewable/recyclable character and their non-toxicity,

- the building is designed to be dismantled easily,

- products and materials are characterized via „circular passports“ on a database where suppliers entered information on the composition of their products, their durability, their recyclability, their potential future uses, their carbon footprint, etc.

Preservation and development of biodiversity:

The project is an ode to biodiversity and the development of life in all its forms and in an ecosystem approach. It is thus designed to benefit all living beings. The construction of the building from healthy products, the limitation of waste discharge and the absence of phytosanitary products; all these choices contribute to the preservation of health and the environment.

Bioclimatic design:

The design of the factory was determined according to the configuration of the site, its topography and its solar gain, in order to make the best use of the various inputs that the natural environment can provide.

Water purification and reuse:

The building’s autonomy with regard to water management – both rainwater and wastewater – is part of the project’s ecosystemic vision. It does not discharge any polluted water and limits water consumption as much as possible, through the recovery of rainwater and the use of flow limiters on all the project’s taps.

Intended Use

Factory and offices

The Team

Project Architect: Atelier d’Architecture HVR

Project Developer: Ulterïa Immobilier

Project Engineers & Contractor: 3IA Ingénierie, VERITAS

Landscape designer: Benjamin Mesnager

Project Advisor: Upcyclea

Project Showcase

Elements

⁂ Enhance Air Quality and Indoor Climate

⁂ User Well-being

Positive Impact

Mobilwood is committed to providing a fulfilling working environment for its employees. All comfort parameters were considered to ensure that the workspaces are both pleasant and ergonomic:

Visual comfort and visibility to the outside. In the workshop, natural light is abundant thanks to large windows and skylights. All work areas (workshops and offices) have windows overlooking the outside. Artificial lighting has been kept to a minimum, with a specific treatment for each workstation to adapt to the needs of each person.

Thermal and hygrothermal comfort. Summer cooling is provided by a natural „adiabatic“ system that cools the air while regulating humidity. Heating is provided by an underfloor heating system and radiant panels, using water heated by the wood chips produced by the factory.

Acoustic comfort. Noise is dealt with by several clever systems that attenuate emission and reverberation. In the workshop, the steel ceiling pan is perforated and acoustic partitions made of wood and wood wool, demonstrating Mobil Wood’s know-how, are installed in strategic locations. In the offices, the entire ceiling is made of wood fibre with wood wool on top, trapping almost all the sound.

Air quality. Particular attention was paid to non-toxicity. The products in contact with the indoor air do not contain any of the substances on the C2C’s „Banned List“ and all the coatings, paints and glues have negligible formaldehyde levels for health. Finally, in the workshop where the wooden furniture is produced, the dust and chips are evacuated by a high-performance ventilation system and then used directly to fuel the wood boiler. The offices are also equipped with an efficient double-flow ventilation system to ensure healthy air. Before/after measurements are taken to compare progress.

Comfort of use. The optimisation of the flow and the manufacturing process was the backdrop for the design of the workshop. The design of the factory was therefore based on simple, obvious and common-sense solutions. Moreover, the building is not limited to a workshop and offices, additional spaces have been designed: a common hall, a mezzanine, … and the employees also have the possibility to work outside.

Benefits

Visual comfort and visibility to the outside. Seeing daylight improves the quality of life at work for employees. The risks associated with overexposure to artificial lighting are the risks of disrupting the natural cycle, generating stress, fatigue and headaches.

Thermal and hygrothermal comfort. Wood is sensitive to humidity and temperature variations, so it was necessary to control these two factors, and of course this also benefits the employees!

Acoustic comfort. The manufacture of wooden furniture requires the use of noisy machines. The treatment of noise is therefore an issue that has been taken into account in the design of the workshop in order to protect the hearing of the employees.

Air quality. Air quality is considered at all levels of the project, from the exterior to the workshop. Mobilwood is committed to preserving the health of its employees by avoiding exposure to pesticides, wood dust, formaldehyde or any other controversial substance.

Comfort of use. Common spaces such as the hall, the mezzanine or the courtyards and corridors allow for people to meet and work together intelligently. These additional spaces give Woodians the opportunity to play sports, relax or have fun on site outside of their working hours.

⁂ Integrate Biological Nutrients, Enhance Air Quality and Indoor Climate, Healthy Materials (Design for Disassembly, Material Re-Use)

Positive Impact

Circular Products & Materials. The products and materials were selected for their renewable/recyclable character and their non-toxicity: wood, stone, hemp, cellular glass, wood wool, zinc… The use of PVC is therefore almost non-existent. For this project, the choices were made towards healthy and circular alternatives: the pipes are made of HDPE or Polypropylene and the joinery is made of wood/aluminium.

´Demountable building design. The building includes workshops (wood and storage workshops), sheds (storage and shipping sheds) and offices. For each of these programs, the structure was designed to be easily dismantled while meeting the expected uses and technical and thermal performances. Most of the elements are dry assembled. The site was designed to be dismantled partially, by area, according to the evolution of the company’s activity over time. Each „function“ of the factory has its own structure which could be dismantled individually.

The structure of the workshops is made of concrete posts fixed by bolting and can thus be easily dismantled. This structure supports a glued laminated timber frame, which can be easily dismantled and whose timber can be reused. The constraints of the building – among others with regard to fire resistance – did not allow the construction of wooden walls. Cellular concrete was therefore used for the façade. Cellular concrete is a single material that acts as a façade, with a 2-hour firewall and insulation.

The structure of the hangars and offices is composed of porticos and a solid wood post and beam structure. All the elements were prefabricated in the workshops.

All the networks are exposed to allow the evolution and dismantling of each layer of the building.

Traceability. For this project, all stakeholders were involved in setting up the building materials bank. The project management selected healthy and circular products and materials, the companies described precisely the quantities and assembly methods of the products used, and the product suppliers shared information on their products via circular passports.

More than 50% of products and materials were characterized via „circular passports“ on a database where suppliers entered information on the composition of their products, their durability, their recyclability, their potential future uses, their carbon footprint, etc. This information allows for conscious product choices at the design stage, but also for the management of these resources over time during the operation of the building.

Benefits

The choice of healthy products and materials helps to protect the health of the building’s users. It can also be noted that the strong presence of wood plays a significant role in the feeling of well-being of users. Recent studies have shown that our body reacts positively to the presence of wood: heart rate is calmed, stress levels are reduced and concentration is improved. Wood has a calming effect similar to that of exposure to nature. This is further enhanced by the low effusivity of this material, which allows a lower temperature to be maintained in the building with an equivalent feeling of comfort, and therefore leads to energy savings.

While bio-based materials have a positive impact on physical and mental health, they are also more easily recyclable and reusable – compared to petrochemical materials, for example, whose non-toxicity is not always proven.

The demountable/modular design of the building has several advantages for users. During the construction phase, the prefabrication of the wood-frame modules has considerably reduced the assembly time on site while limiting the production of dust and noise pollution. Then, during the life of the building, its dismantlability will allow exceptional modularity of use. The layout inside the volumes is free and can evolve according to needs. Today, a mezzanine has been fitted out in the office area, but tomorrow a completely different interior design could be envisaged!

The characterisation of products and materials via circular passports is a new approach in the design/construction of buildings. Although it has not always been easy to obtain information from product manufacturers, this approach allows us to question various issues that are still not given sufficient consideration. These include the design of healthy spaces for users, the fight against the depletion of resources through the use of bio-based or recycled materials, and the reduction of waste generated by anticipating the recycling/reuse of building components.

All the data accumulated on products and materials is organised in a „material library“. Thus, future managers have the tools to manage the building’s resources throughout its life and beyond!

⁂ Actively Support Biodiversity

Positive Impact

Inscribing the project in the landscape. The landscape design aims to place the building in its rural context, as well as to preserve and nourish the existing landscape entities. By connecting to the natural areas around the site, the project constitutes a „biological corridor“.

Eco-responsible management of green spaces. The choice of plantings respects the soil and climate conditions, in order to encourage biodiversity and the diversity of plant species. The landscaping is designed to require as little maintenance and watering as possible. No chemical weeding is prescribed. This creates a balanced ecosystem of flora and fauna in a sustainable landscape approach. The evolution of the climate towards harsher summers has also been taken into account in the choice of species.

Biodiversity refuges. The new species planted are endemic and/or adapted to local climatic conditions, with the aim of increasing and enhancing biodiversity. Several landscaped areas: „the garden of possibilities“ and „the workshop clearing“, on either side of the offices, offer a diversity of endemic, herbaceous and shrubby plants.

All the planted areas are covered with RCW (Ramial Fragmented Wood) to boost the microbial biodiversity of the soil. A pond of approximately 300 m² brings animal life to the site, and is a relay for amphibians, pipistrelles, birds and insects. This water bridge makes the project part of the territory’s green and blue framework. Beehives have also been installed.

A 5,000 linear meter hedge, composed of a mixture of local, shrubby, edible and melliferous plants, borders the plot. In addition to delimiting the land and providing protection against wind and frost for nearby plantations, it provides a home for animal species and thus creates biological corridors.

Benefits

The project is an ode to biodiversity and the development of life in all its forms and in an ecosystem approach. It is thus designed to benefit all living beings. The construction of the building from healthy products, the limitation of waste discharge and the absence of phytosanitary products; all these choices contribute to the preservation of health and the environment.

In addition, the landscape qualities of the site contribute to the well-being of the people who work there. In fact, during their breaks, the Woodians can enjoy the gardens near the plant. These gardens also have an educational purpose, that of helping people discover local species, and others that are rarer.

⁂ Natural Lighting

⁂ User Well-being

Positive Impact

The design of the factory was determined according to the configuration of the site, its topography and its solar gain, in order to make the best use of the various inputs that the natural environment can provide.

The steel and polycarbonate workshop roofing provide free solar gain in winter, which helps to heat the company, and in summer, the natural draught provides enhanced ventilation.

On all the buildings, skylights are placed on the roof and on the south facade. They capture the sun’s natural heat in winter and limit the need for artificial lighting to over 40%.

In order to meet the requirements for summer comfort, it was necessary to have a system for cooling the air. The choice was made for adiabatic cooling, which is one of the most economical and ecological solutions: the hot air passes through a wet exchanger. As the water evaporates, it absorbs the heat from the air, thus cooling it.

The insulation of the building plays an important role in the energy design. The challenge was therefore to select insulation materials that are thermally efficient, yet healthy and made from bio-based or recycled materials.

For the offices, the insulation of the walls and roof is made of wood wool and the insulation under the slab is made of cellular glass – 66% of which is made from recycled materials (limestone from windscreens). For the workshops, the insulation on the facade is provided by cellular concrete, whose inertia enables it to store heat or coolness and to release it gradually, thus naturally regulating the temperature and humidity inside the building.

Benefits

Bioclimatic design is a design of the building in phase with its environment, it participates in renewing the links between Man and nature. This vision is both positive for men, whose well-being is improved, and for the environment, which is an integral part of the project. With its large glass surfaces, the building is turned towards the outside and dialogues with the landscape. Wherever you are in the building, you have a view of the outside. The generous amount of natural light also contributes to user comfort.

The complex issues of thermal comfort linked to the large volumes of the workshops and their industrial use were taken into account and dealt with via all the principles detailed above. In particular, the choice of adiabatic air conditioning provides a more comfortable level of humidity in the air than that generated by air conditioners – traditionally used in office buildings – which are often too dry and can cause sore throats and headaches.

⁂ Integrated clean energy production

Positive Impact

Heating autonomy. The heating of the buildings and the process is provided by a wood boiler room. Current techniques have improved the efficiency of this system by up to 90% while reducing the smoke and pollutants generated. The boiler room is fuelled 100% by wood waste from the plant’s operations – pallets, production offcuts and sawdust – and represents an important energy resource. Some of the heat from the workshop compressors is also recovered, which contributes to up to 10% of the heating requirements.

Electrical panels. More than 1200m2 of photovoltaic panels are used in this project, of which 336m2 are installed on the roofs of the south-facing sheds – storage, shipping and covered courtyard. The roofs are sloped at 30° to maximize solar gain.

The panels are supplied by TRINA, which has been ranked as one of the most cost-effective solar panel manufacturers in the world by Bloomberg New Energy Finance.

Benefits

The Wood boiler room cover 100% of the heating needs.

Photovoltaic panels cover 100% of the electricity and domestic hot water needs, excluding the process, making the project largely energy positive.

⁂ Enhance Water Quality, Water Management

Positive Impact

On-site rainwater management. Rainwater is managed and infiltrated on the site via several ditches (at the edge of the plot and near the roads), a 200m3 fire reserve basin, a 260m3 watertight basin, and several infiltration basins. Rainwater from the heavy goods vehicle roadway is collected by a network of gullies that redirect it to the infiltration basin. They are treated by a hydrocarbon separator.

On approximately 70% of the plot, a sufficient thickness of vegetated land allows for the infiltration of rainfall volumes, and the eco-foam parking spaces are also permeable. The rainwater on the roof of the building is collected via a peripheral network on the roof and then evacuated to an infiltration basin.

Rainwater recovery. A tank has been sized according to the site’s rainfall (capacity of 45 m3) and is connected to more than 800 m² of impermeable roofing. This sizing enables all the needs of the production site and offices to be covered, for the uses authorised by the regulations in force (sanitary facilities and watering).

In addition, using rainwater limits discharges into the municipal water system (limited to 21/s/ha according to regulations).

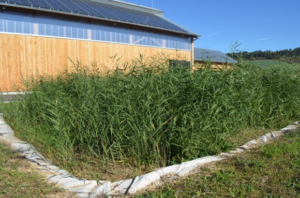

Wastewater management. All the wastewater from Mobil Wood’s activity – water related to the activity, sanitary water, wastewater from the restaurant and the social premises – is treated by a phyto-purification plant. The site is thus completely autonomous, not connected to the municipal wastewater network, and does not discharge any liquid waste. This treatment plant is designed to be scalable. As needs arise, it can evolve and be expanded.

Benefits

The building’s autonomy with regard to water management – both rainwater and wastewater – is part of the project’s ecosystemic vision. It does not discharge any polluted water and limits water consumption as much as possible, through the recovery of rainwater and the use of flow limiters on all the project’s taps.

Delights

Positive Impact

The Mobil Wood factory project in Saint-Bris is part of a larger project, the „Ulterïa Saint-Bris“ project, which brings together several organisations sharing a common vision, that of becoming an „ecosystem that creates value for people and the living“.

This unique project combines agricultural activities (with an organic goat farm – La ferme d’Ulterïa), educational activities (with a Montessori school – l’école Elise – and a training centre – Ulterïa Formation), social activities (with an eco-citizen’s house) and industrial activities (with the Mobil Wood carpentry). In Saint-Bris le Vineux, a plot of land was acquired in 2017 in order to create a common project for these structures. This project is in itself unprecedented and requires skills that are relatively rare in France. As a consequence, it has mobilized experts in their respective fields (architecture, Cradle to Cradle consultants, design engineers, landscape designers, permaculturists, etc.) in order to invent new and essential solutions to bring about the changes that Mobil Wood wishes to implement.

Benefits

This project aims to demonstrate that it is possible to energise a territory and innovate in a frugal way. This 10-hectare project is intended to be a demonstrator of a new form of „major real estate project“ that creates meaning and can be developed by small and medium-sized enterprises.

Through the diversity of programs developed: associations, eco-citizen house, training centre, Montessori school and farm, the aim is to create a positive emulation on this territory. By thinking of the project in a global way, the proposed services will be able to complement and respond to each other. It is a question of interconnecting, on the same territory, activities that cover four major human needs: transmitting and learning, creating links, working and eating.

Positive Impact

The location, close to hiking trails, wine sites and major tourist routes in the region, provides a certain visibility for the project which can thus attract the interest of tourists. Site visits are also organised to communicate the philosophy of the project.

Regarding communication about the Mobil Wood activity in particular, a showroom located at the entrance of the factory allows visitors to discover the products designed on site. Visitors can immerse themselves in the atmosphere of the factory through the view of the assembly workshop. The building itself is in line with the furniture produced there and is a showcase for eco-furniture.

The Mobil Wood factory also wishes to develop an incubator to test and develop new activities and to host innovative start-ups in their premises. Several projects are already under study:

- Development of a new shopfitting concept (intrapreneurship)

- Distribution of organic baskets from the permaculture area

- On-site construction of Montessori educational material

- Food processing of organic products

- Accompanying companies in the transition to innovative governance models

The project includes an accredited training centre, attracting both trainers and trainees. It will also be possible to rent this centre.

Benefits

The Mobil Wood factory and offices, like the Ulterïa ecosystem, are two projects that are not intended to remain isolated. On the contrary, it is a question of spreading this culture, which creates values for people and the environment, beyond Saint-Bris!

Through the design of its factory, Mobil Wood wishes to transmit an image of quality, that of a building turned towards the future and evolving, anticipating possible evolutions of the company’s project like a demonstrator of the values carried by the company and the quality of its work. And with its incubator, Mobil Wood goes further, in a process of continuous improvement and innovation.